FEBRUARY 25, 2022 by Tina Hilding, Washington State University

A long-overlooked first step in developing sustainable aviation fuels is to begin with the right configuration of molecular ingredients.https://6d97160c9af603c20c937d4a955803c4.safeframe.googlesyndication.com/safeframe/1-0-38/html/container.html

A team of Washington State University and Pacific Northwest National Laboratory (PNNL) researchers has recently found the ideal atomic interaction and the best place to start is the catalytic conversion of lignin, the most abundant plant material on earth, to ingredients for aviation fuels. The work has been published in the journal Frontiers in Energy Research.

“This is kind of ground zero—the first thing that you need for a useful model,” said Jean-Sabin McEwen, associate professor in the Gene and Linda Voiland School of Chemical Engineering and Bioengineering and co-corresponding author on the paper.

In seeking to address global warming, the aviation industry has committed to reducing its carbon emissions in half by 2050. The research team claims that sustainable, bio-based fuels offer a promising alternative to petroleum-based fuels and could reduce emissions by 80%. Because of its worldwide abundance, the woody, inedible parts of plants known as lignocellulose would be a prime candidate. Converting it cheaply and efficiently to the necessary ingredients has been challenging, however.

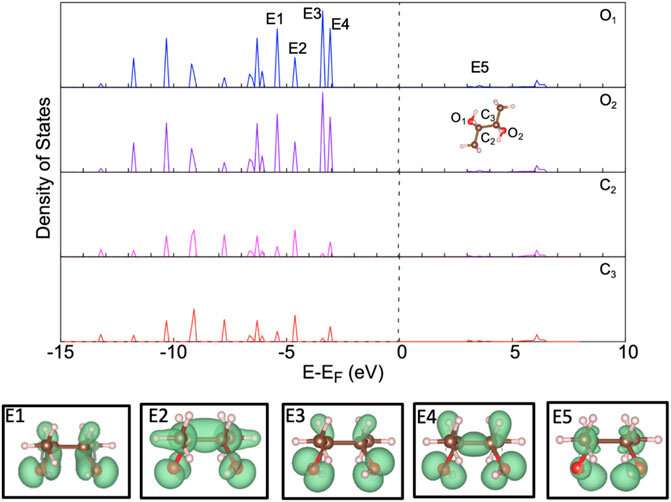

One possibility is to convert a lignin-derived alcohol to butene, a useful ingredient for jet fuel. But having the optimal set-up at the molecular level between the complex alcohol molecule and the catalyst needed for the reaction is critically important for using the least amount of energy later on. Researchers have to have computational models that accurately represent experimental conditions.

“If you have a bad starting structure, then you end up spending a lot of computer time on a reaction that may not be relevant” said Vassiliki-Alexandra (Vanda) Glezakou, a senior researcher at PNNL and co-corresponding author on the paper. “Here we are able to focus on the right molecular arrangement, and we’re actually learning how atoms and molecules interact in order to have this reaction happen. We can also build upon this learning for other systems.”

The alcohol molecule in this case has four, zig-zagging carbon atoms and two groups of hydrogen and oxygen molecules. The catalyst is ruthenium oxide. It has not been known exactly how the molecules will interact with the surface of the catalyst and where each of the carbon atoms will go. With poor understanding of the fundamental reaction that brings the two molecules together, researchers instead have undertaken complex and expensive calculations, but without finding the optimal solution for the reactions.

“If you want to design a catalyst rationally you need to understand how the reaction proceeds in the first place, and that is extremely complex,” McEwen said.

For their fundamental study, the researchers used a global optimization program that Glezakou and team recently developed called the Northwest Potential Energy Surface Search Engine (NWPEsSe) , which is publicly available for other researchers to download and use, to find the best set-up for the molecules. Beginning with about 20,000 different configurations, the computer program then analyzed, ranked, and provided a handful of the best, most energetically favorable structures.

“This would be absolutely impossible with the code I would usually be using,” said McEwen. “I’m not sure I could do 20,000 structures in my lifetime.”

The researchers hope the computer program can be used in the future to better design catalytic reactions and to improve other complicated and challenging industrial chemical conversion processes.

“Luckily, NWPEsSe can help with problems like that,” said Glezakou.

More information: Carrington Moore et al, Determining the Adsorption Energetics of 2,3-Butanediol on RuO2(110): Coupling First-Principles Calculations With Global Optimizers, Frontiers in Energy Research (2022). DOI: 10.3389/fenrg.2021.781001

Provided by Washington State University