Joshua Sadlock, Jun 22, 2021

Collected at: https://www.engineering.com/story/foghorns-real-time-analytics-set-to-drive-the-future-of-iot-and-business-intelligence?utm_source=engineering.com&utm_campaign=08704fc5e3-EMAIL_CAMPAIGN_7_12_2018_8_42_COPY_01&utm_medium=email&utm_term=0_622b2cc90f-08704fc5e3-323001813

The future of data analytics is in edge computing, not on the cloud, and Foghorn is making early headway in the field.

The very earliest days of the COVID-19 pandemic were some of the strangest ever for the global economy. Toilet paper, Clorox wipes and hand sanitizer became precious commodities, with grocery stores picked clean almost as soon as they restocked their shelves. Meanwhile, the price of a barrel of oil briefly went negative with available storage at all-time lows. The virus may be on the retreat as vaccine rollout continues to ramp up—another logistical challenge if ever there was one—but supply chains are still out of whack. Chip shortages have gotten so bad that used cars are actually appreciating in value while automakers struggle to meet the demand for new vehicles. The price of lumber has nearly been cut in half since peaking in May but is still up just shy of 200 percent over the past year.

It’s been a nutty 16 months since the coronavirus first forced us to reconsider nearly everything about how we do business, and the ripple effects and aftershocks of shutting down virtually the entire world economy for a short time period are still being felt and could be for quite some time. One Silicon Valley startup, however, believes it has the solution to help companies work through the gyrations of consumer demand and running its operations more efficiently.

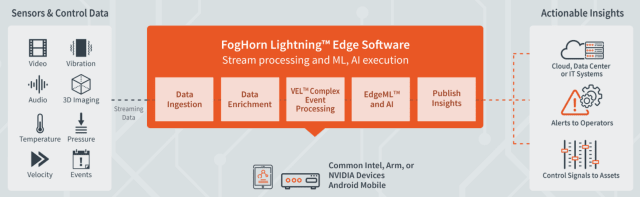

Founded in 2015, Foghorn is one of the first movers in edge computing for AI and machine learning applied to industrial businesses and producers of consumer-packaged goods. Foghorn is different from its competitors in the business analytics space. Unlike its competition, Foghorn’s data analytics platform runs on the edge of the internet, rather than functioning like traditional software that operates by sending data to the cloud and analyzing it remotely. By operating on the edge, Foghorn is able to process data in real-time right at the source where it is being generated.

The industries Foghorn targeted as its primary user base are hardly the typical sexy clientele that Silicon Valley startups go after. GE, Honeywell and Bosch were key early investors and backers of the company, as was oil and gas giant Saudi Aramco. For companies in the heavy industrial and oil and gas industries, machinery and production lines generate millions of data points every day. A data analytics platform that operates in real-time rather than on a delay as data is passed back off location to the cloud has the potential to unlock massive value.

“At the edge, we’re able to act on the equipment inside of facilities in a second-by-second, minute-by-minute basis, to drive optimal energy efficiency, looking at everything from schedules to an occupancy, to the weather conditions, to the cost of energy,” explained Chris Penrose, Foghorn COO. “We’re able to do all that in real-time to drive optimal savings. It also, interestingly, is something we took into manufacturing early on, as well with this idea around being able to look down at the actual assets themselves inside of a factory, and how are they pulling energy and in being able to identify anomalies that might lead to potential prediction of failure of equipment so we can maximize uptime and productivity.”

One area that was particularly interesting for Foghorn during the pandemic was the consumer-packaged goods industry. The entire sector was under immense pressure as consumer demand was turned upside down in the blink of an eye. Not only were consumers forced to do almost all of their cooking and snacking at home in the early days of quarantine, but human behavior was also wildly irrational. Hoarding toilet paper, anyone?

Foghorn deployed its technology in the CPG space to help clients improve and optimize yield, ensuring that the same amount of product goes into the package every single time with no waste. This is crucial for companies who are under a crunch to produce and ship more goods than ever before while also facing labor and materials shortages. Analyzing data on the edge makes it possible to take action immediately. Penrose laid out the unique application of Foghorn’s edge analytics.

“I think in our CPG use case that we put out there how we could right process in real-time, what we were seeing in the way of fill of a particular bottle and product was to make sure that we were not underfilling or overfilling that product to make sure we got the optimal yield for the facility. In that case, our platform was deployed to initially begin to alert when we were seeing deviation in the yield, but then ultimately be able to control back into the line in real-time to be able to speed up or slow down the flow to get a consistent yield each time. That’s one of the things I think is really unique about Foghorn is that closed-loop approach where a lot of analytics can be done, where they can give you an insight and have some good take out. At Foghorn, we go that step further where we can not only give you the insight, but we can also close the loop and take the action on that insight instantaneously.”

When it comes to data analytics in the world of business, manufacturing and facilities operation, it’s a race to be able to see data in real-time and act on it immediately. That is the biggest selling point for a platform like Foghorn. The pace at which data is being generated in the wild is increasing exponentially, but much of its value is lost if it cannot be acted on in the blink of an eye. The applications for real-time data analytics are endless, and Foghorn is ready to continue pushing forward.

“When these huge volumes of data are being created, it does become both cost prohibitive to try to send all that data off-site to then be analyzed and then bring it back. You also have that incremental latency of having to round trip that data versus if you can act on all that data right there as it’s being created. In these scenarios, because the datasets can be really heavy, people sometimes down sample the data and will only send portions of the data off to the cloud. They can get a lot of false positives or not get a full view. So the models, we actually call it cheaper, better and faster. We think in certain cases the models can actually be better on our platform because we’re seeing all the data right at the source of data versus a down sampled party or that most high-fidelity data. You’re just passing the insights out versus passing all the data.”

Besides the obvious selling point of being able to analyze data in real-time, Foghorn has additional value for users because of how adaptable and simple the platform is to use. This ability becomes even more important as more and more devices come with IoT capability and are able to communicate directly with each other and share data.

“We can take in any type of sensor data, from temperature and pressure to video and audio vibration, and adjust all that data, enrich it and then start running it through our complex event processing engine, applying our algorithms, then applying AI and publishing those insights out through a variety of ways. We’re really sensor agnostic, and we’re really transport agnostic. The data could come in through any kind of activity, and we just need to get the stream into our platform.”

(Image courtesy of Foghorn.)

Lest you think that Foghorn’s data analytics is all about yield and energy efficiency, there is also a strong health and safety component. As manufacturing facilities and packing plants re-opened during the height of the pandemic, Foghorn clients turned to the company to help them implement video and temperature monitoring to ensure social distancing practices were being followed correctly. On dangerous job sites, the platform can also be used to monitor employee use of personal protective equipment.

Data analytics plays a massive role in global commerce, and its role will only become more crucial as artificial intelligence (AI) makes it possible for processes to be controlled in the background without human monitoring or input. Foghorn believes it can help get us there, and the early results certainly back up the company’s case. The platform is built to adapt on the fly and process every type of data point that can possibly be generated. Data on the edge is the future, and Foghorn is happily sounding the message.