November 25, 2025 by Anette Mack, Steinbeis Europa Zentrum

Collected at: https://phys.org/news/2025-11-plasma-catalytic-aims-livestock-methane.html

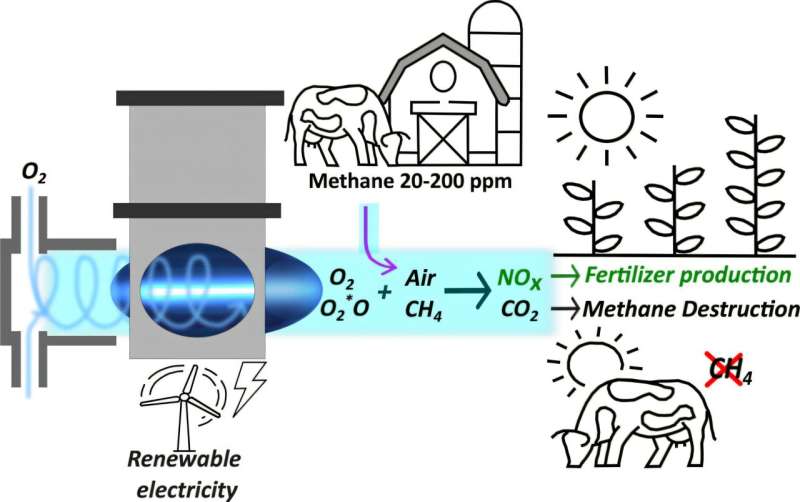

The CANMILK project is developing a plasma-based system suitable for direct operation in barns to reduce methane emissions from livestock. The goal is to capture dilute methane present in barn air and convert it into CO₂ through the combined action of plasma and catalytic processes. As a low-TRL project, CANMILK is highly focused on research and development, working on optimizing the design of adsorber, catalyst and plasma components and how they best work together.

This requires continuous evaluation of the results and re-adjustment of the system as development work progresses. All components are being integrated into a proof-of-concept (PoC) unit, which will be tested with simulated barn air. This PoC is designed to demonstrate the basic concept, allowing the project team to validate their experimental ideas and optimize the system’s performance under realistic conditions.

In parallel, a techno-economic assessment is underway to analyze both the economic feasibility of the technologies and the physical properties of the emissions, with the aim of aligning technical performance with market-ready solutions.

As one of the project partners, Steinbeis Europa Zentrum supports the development and implementation of the communication and dissemination strategy and the definition of the exploitation strategy for the project. It supports the management of intellectual property.

Research activities

CANMILK’s research is structured around five main topics: Plasma Modeling and Diagnostics, Adsorbent and Catalyst Development, Activated Gas-Surface Interactions, Process Concept Development, and Techno-Economic Assessment.

Several publications were produced based on the conducted research. They include the following journals: ACS Omega, two in Plasma Sources Science and Technology, Green Chemistry and the Chemical Engineering Journal.

A short summary of the main achievements from the first three years, as well as the planned next steps, will be provided in the following sections.

Plasma modeling and diagnostics

Understanding plasma chemistry for the abatement of dilute methane is a core focus of the CANMILK project. The University of Antwerp has created models to simulate the chemical reactions and gas flows in O₂ and H₂ plasma reactors. Combined with experimental findings from the University of Maastricht, these results indicate that warm O₂ and H₂ plasmas are not efficient for removing low CH₄ concentrations.

Looking for alternative approaches, further results indicated that the use of barn-air plasma has the potential for methane reduction. However, this approach also produces NOx, which is typically considered an emission, though they may be further utilized.

These findings prompted the CANMILK partners to revise their strategy, exploring the alternative pathway of using air plasma to enhance feasibility and scalability. In line with this revised approach, UA developed a novel fluid model for microwave air plasma. Next steps include comparing the model with experimental measurements from UM and optimizing operating conditions for integration into the PoC unit.

Adsorbent and catalyst development

Developing materials capable of concentrating methane is crucial due to the very low methane levels in barn air. Experimental screening has identified promising adsorbents that could potentially increase methane concentrations from 20–200 ppm to 200–2000 ppm, facilitating more efficient downstream processing. In parallel, catalysts were prepared and evaluated for compatibility with the plasma system, including structured honeycomb materials and powders.

Activated gas-surface interactions

To gain a deeper understanding of plasma–catalyst interactions, theoretical and experimental studies were initiated by project partner Técnico Lisboa. The researchers are developing mesoscopic surface kinetics models to describe the interactions between plasma-generated gas species and catalyst surfaces, along with catalysts for CH₄ oxidation using various radicals and biowaste-derived supports.

Proof-of-concept unit

In order to demonstrate the integration of plasma, catalyst, and adsorber technologies for methane reduction in barn air, project coordinator VTT is developing a PoC unit, allowing the project team to validate experimental concepts and optimize system performance under realistic conditions.

The design process has been highly collaborative, with all project partners actively participating in monthly design discussions. Technical and safety aspects have been carefully evaluated, ensuring that the system meets operational and regulatory requirements. The unit is being built as a movable system to facilitate flexible testing and adaptation. Construction of the PoC unit is underway at VTT’s Bioruukki testing facility, with commissioning and experimental testing scheduled for the next phase approximately in November 2025.

Techno-economic assessment

Assessing the techno-economic feasibility is a crucial step in the CANMILK project, ensuring that the developed methane reduction technologies are not only effective but also practical and cost-efficient for real-world implementation in dairy farming. Advanced simulations of a working dairy barn have provided insights into methane dispersal and the need for controlled ventilation to maximize capture.

Multiple system configurations combining plasma, catalyst, and adsorber technologies have been designed and modeled, allowing the team to estimate capital and operating costs, as well as the cost per kg of methane removed. These analyses help identify the most economically viable approach for full-scale implementation. Next steps will focus on refining economic assumptions and performing a life cycle analysis to support market-ready solutions.

More information: Stijn Helsloot et al, Trace Methane Destruction within the Effluent of Microwave Plasma, ACS Omega (2025). DOI: 10.1021/acsomega.4c10550

Matthias Albrechts et al, Investigation of O atom kinetics in O2 plasma and its afterglow, Plasma Sources Science and Technology (2024). DOI: 10.1088/1361-6595/ad3f4a

Pedro Viegas et al, Role of volume and surface processes in the atomic oxygen loss frequency in oxygen glow discharges in Pyrex, Plasma Sources Science and Technology (2025). DOI: 10.1088/1361-6595/adf5e4

Matthias Albrechts et al, Can post-plasma CH4 injection improve plasma-based dry reforming of methane? A modeling study, Green Chemistry (2024). DOI: 10.1039/d4gc02889a

Abhinash Kumar Singh et al, Non-thermal plasma assisted methane oxidation inside a DBD reactor: Effect of monometallic catalyst on energy efficiency and CO2 selectivity, Chemical Engineering Journal (2025). DOI: 10.1016/j.cej.2025.166610

Journal information: Chemical Engineering Journal , Green Chemistry , ACS Omega

Leave a Reply