December 23, 2025 by Paul Arnold, Phys.org

Collected at: https://phys.org/news/2025-12-reactor-energy-carbon-nanotubes-natural.html

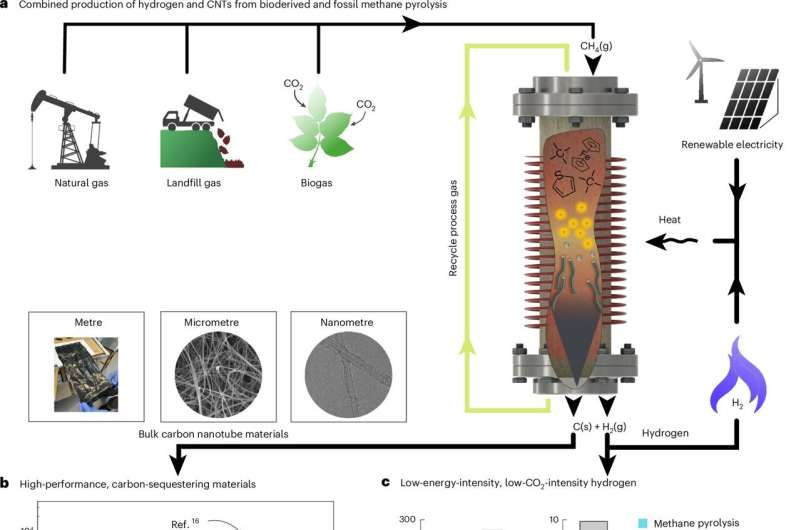

Scientists from the University of Cambridge have developed a new reactor that converts natural gas (a common energy source primarily composed of methane) into two highly valuable resources: clean hydrogen fuel and carbon nanotubes, which are ultralight and much stronger than steel.

Hydrogen is a promising green fuel because it burns completely, producing only water vapor and zero carbon dioxide. However, the way we make hydrogen today typically involves using high-pressure steam to break apart gas molecules, which releases significant amounts of CO2 as a byproduct.

To avoid this, the Cambridge team wanted to perfect a technique called methane pyrolysis, which converts methane into hydrogen and solid carbon without producing carbon dioxide. However, until now, no one has been able to perform this process efficiently enough for large-scale use because traditional reactors waste too much gas.

Multi-pass reactor

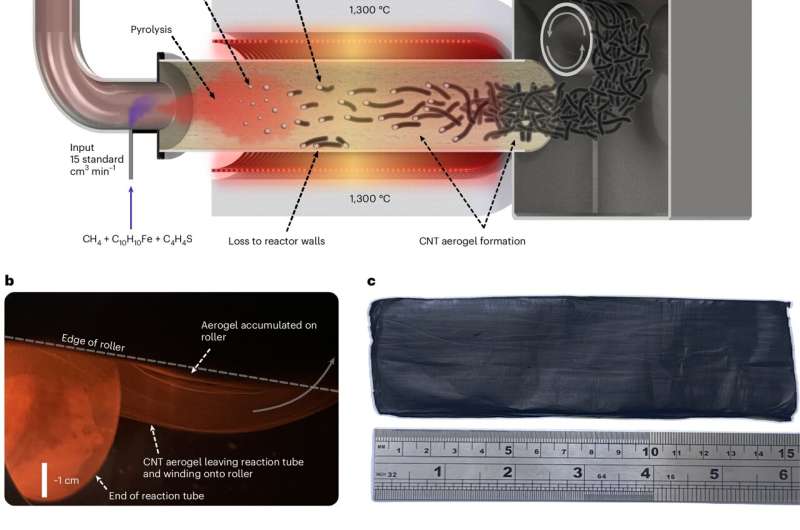

The scientists solved the problem by building a multi-pass reactor, as detailed in a paper published in the journal Nature Energy. Instead of letting the gas pass through the system only once, which results in significant waste and lost energy, the unused gas is continuously recycled. The methane keeps passing back through the hot reactor until most of it is converted into hydrogen and carbon nanotube aerogels.

By operating as a closed-loop system, the reactor minimizes the amount of material that is wasted. This approach resulted in a massive leap in performance when compared to single-pass reactors, as the researchers report in their paper: “The multi-pass reactor demonstrated an 8.7-fold improvement in carbon yield and 446-fold improvement in molar process efficiency [how efficiently the system used every gas molecule].”

Methane pyrolysis to produce hydrogen and bulk CNT materials from methane. Credit: Nature Energy (2025). DOI: 10.1038/s41560-025-01925-3

From lab to the real world

The study was conducted on a lab-scale reactor, but to see how the multi-pass system would perform in the real world, the researchers ran a computer model of a larger version designed for industrial use. They incorporated data from a real commercial plant to make the simulation as accurate as possible.

The team found that the loop design would convert 75% of the gas entering the system into useful resources, producing carbon nanotubes and hydrogen in a 3:1 mass ratio. In other words, for every 4 kilograms of methane the system successfully converts into useful resources, it makes 3 kilograms of nanotubes and 1 kilogram of hydrogen.

Not only would this process produce stronger, more sustainable materials for the construction industry, but it would also provide plenty of clean fuel for our energy needs. But before that, there is still a lot of development work ahead. As the researchers note, “The process could reduce greenhouse emissions, but considerable development is needed to deploy this technology on a meaningful scale.”

More information: Jack Peden et al, Production of hydrogen and carbon nanotubes from methane using a multi-pass floating catalyst chemical vapour deposition reactor with process gas recycling, Nature Energy (2025). DOI: 10.1038/s41560-025-01925-3

Journal information: Nature Energy

Leave a Reply