December 22, 2025 by The Korea Advanced Institute of Science and Technology (KAIST)

Collected at: https://techxplore.com/news/2025-12-ai-driven-molding-decisions-multiple.html

Most of the plastic products we use are made through injection molding, a process in which molten plastic is injected into a mold to mass-produce identical items. However, even slight changes in conditions can lead to defects, so the process has long relied on the intuition of highly skilled workers.

Now, KAIST researchers have proposed an AI-based solution that autonomously optimizes processes and transfers manufacturing knowledge, addressing concerns that expertise could be lost due to the retirement of skilled workers and the increase in foreign labor.

A research team led by Professor Seunghwa Ryu from the Department of Mechanical Engineering has developed the first generative AI technology that autonomously optimizes injection molding processes, along with an LLM-based knowledge transfer system that makes on-site expertise accessible to anyone.

The results were published in the Journal of Manufacturing Systems.

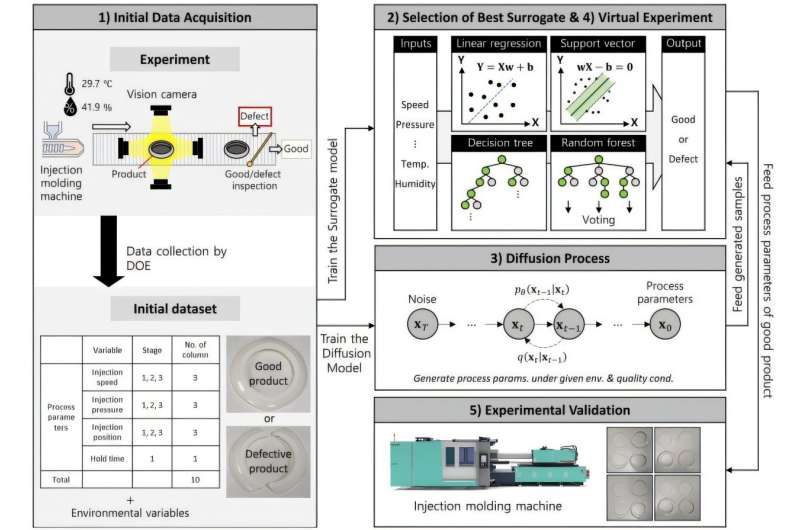

The first achievement is a generative AI–based process inference technology that automatically infers optimal process conditions based on environmental changes or quality requirements. Previously, whenever temperature, humidity, or desired quality levels changed, skilled workers had to rely on trial and error to readjust conditions.

The research team implemented a diffusion model-based approach that reverse-engineers process conditions satisfying target quality requirements, using environmental data and process parameters collected over several months from an actual injection molding factory.

In addition, the team built a surrogate model that substitutes for actual production, enabling quality prediction without running the real process. As a result, they achieved an error rate of just 1.63%, significantly lower than the 23~44% error rates of representative existing technologies such as GAN and VAE models traditionally used for process prediction.

Experiments applying the AI-generated conditions to real processes confirmed successful production of acceptable products, demonstrating practical applicability.

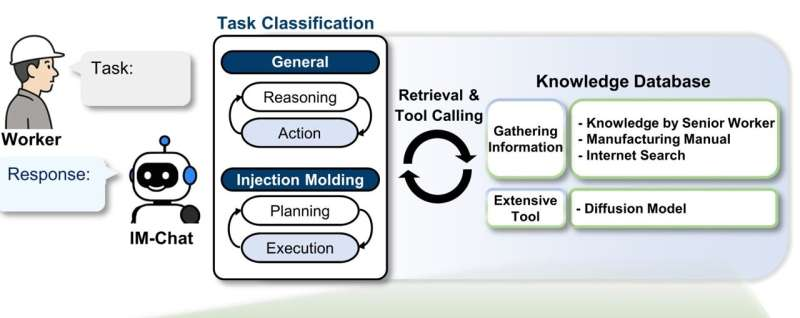

Large language model–based multilingual knowledge transfer multi-agent IM-chat. Credit: The Korea Advanced Institute of Science and Technology (KAIST)

The second achievement is the IM-Chat, an LLM-based knowledge transfer system designed to address skilled worker retirement and multilingual work environments.

IM-Chat is a multi-agent AI system that combines large language models (LLMs) with retrieval-augmented generation (RAG), serving as an AI assistant for manufacturing sites by providing appropriate solutions to problems encountered by novice or foreign workers.

When a worker asks a question in natural language, the AI understands it and, if necessary, automatically calls the generative process inference AI, simultaneously providing optimal process condition calculations along with relevant standards and background explanations.

For example, when asked, “What is the appropriate injection pressure when the factory humidity is 43.5%?”, the AI calculates the optimal condition and presents the supporting manual references as well. With support for multilingual interfaces, foreign workers can receive the same level of decision-making support.

This research is regarded as a core manufacturing AI transformation (AX) technology that can be extended beyond injection molding to molds, presses, extrusion, 3D printing, batteries, bio-manufacturing, and other industries.

In particular, the work is significant in that it presents a paradigm for autonomous manufacturing AI, integrating generative AI and LLM agents through a Tool-Calling approach, enabling AI to make its own judgments and invoke necessary functions.

Professor Seunghwa Ryu explained, “This is a case where we addressed fundamental problems in manufacturing in a data-driven way by combining AI that autonomously optimizes processes with LLMs that make on-site knowledge accessible to anyone.” Adding, “We will continue expanding this approach to various manufacturing processes to accelerate intelligence and autonomy across the industry.”

This research involved doctoral candidates Junhyeong Lee, Joon-Young Kim, and Heekyu Kim from the Department of Mechanical Engineering as co–first authors, with Professor Seunghwa Ryu as the corresponding author.

More information: Joon-Young Kim et al, Development of an injection molding production condition inference system based on diffusion model, Journal of Manufacturing Systems (2025). DOI: 10.1016/j.jmsy.2025.01.008

Junhyeong Lee et al, IM-Chat: A multi-agent LLM framework integrating tool-calling and diffusion modeling for knowledge transfer in injection molding industry, Journal of Manufacturing Systems (2025). DOI: 10.1016/j.jmsy.2025.11.007

Leave a Reply