December 3, 2025 by National Research Council of Science and Technology

Collected at: https://techxplore.com/news/2025-12-era-gas-refrigerants-magnetic-cooling.html

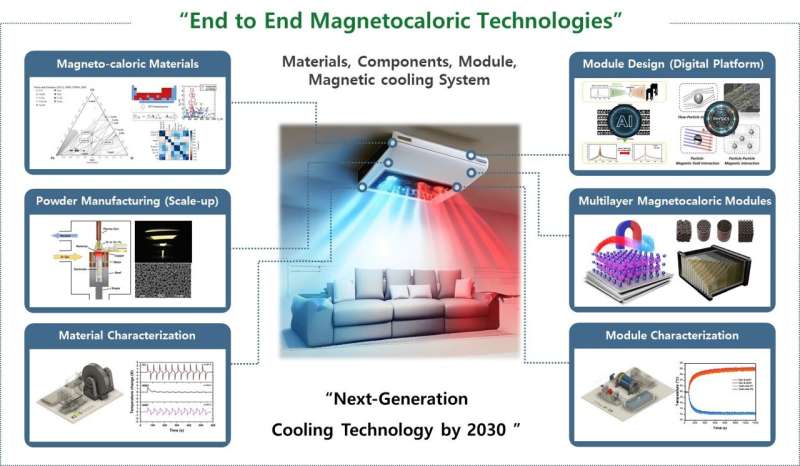

A research team at the Korea Institute of Materials Science (KIMS) has successfully developed Korea’s first full-cycle magnetic cooling technology, encompassing materials, components, and modules.

The paper is published in the journal Rare Metals.

This breakthrough is expected to address the environmental issues associated with conventional gas-based refrigeration technologies and pave the way for eco-friendly, high-efficiency alternative cooling solutions to enter the market.

How magnetic cooling technology works

Magnetic cooling technology is an eco-friendly alternative that enables cooling in the solid state without using gas refrigerants. It operates based on the magnetocaloric effect, in which the temperature of a refrigerant material changes when an external magnetic field is applied.

However, the commercialization of this technology has faced challenges due to the high manufacturing costs of magnetocaloric materials and their dependence on rare-earth elements, making it difficult to ensure price competitiveness. In addition, there have been technological limitations in achieving mass production—particularly in the manufacturing of large-area plates and fine wires required for industrial applications.

Advances in materials and fabrication

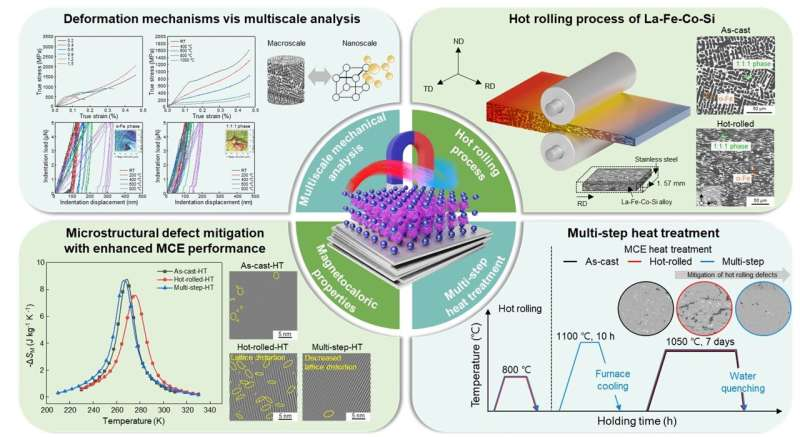

The research team, led by Dr. Jong-Woo Kim from the Nano Materials Research Division and Dr. Da-Seul Shin from the Materials Processing Research Division, synthesized various magnetocaloric materials, including lanthanum (La)-based and manganese (Mn)-based alloys, and successfully fabricated sheet and fine-wire specimens through a series of processes such as hot rolling, cold drawing, and micro-channel machining.

Abstract image of the paper published in Rare Metals (development of large-area sheet manufacturing technology for La-based magnetic refrigerant materials. Credit: Korea Institute of Materials Science (KIMS)

These advanced fabrication techniques enabled near-net shaping through an optimized forming process, thereby enhancing cooling efficiency and reliability. In particular, the team achieved large-area La-based thin sheets (0.5 mm thick) during the forming process and Gd-based fine wires with a diameter of 1.0 mm during wire fabrication—demonstrating world-class performance at the component level.

In addition, for non–rare-earth Mn-based materials, the research team achieved improved cooling performance by controlling thermal hysteresis and adjusting magnetic anisotropy.

Furthermore, the team developed and implemented Korea’s first measurement system capable of directly monitoring adiabatic temperature changes in magnetic cooling materials and components. This breakthrough enabled the quantitative verification of process-dependent property differences and made it possible to develop optimized materials, components, and modules for magnetic cooling applications.

Global trends and future prospects

Globally, regulations on refrigerants are becoming increasingly stringent. Under the Kigali Amendment to the Montreal Protocol, the production and use of major gas refrigerants—including HFCs, HCFCs, and R22—will be completely banned after 2030.

In addition, the use of disposable refrigerant containers, including recycled refrigerants, will also be strictly prohibited. Moreover, in technologically advanced countries such as Germany, a number of research studies and demonstration projects have reported magnetic cooling systems exhibiting coefficients of performance (COP) higher than those of conventional refrigeration methods.

This trend underscores that magnetic refrigeration technology is emerging as a next-generation core cooling solution in the global market. In line with these global decarbonization policies and climate change initiatives, the development of eco-friendly alternative cooling technologies has become a necessity rather than an option.

To respond to this trend, the KIMS research team continues to strengthen its technological competitiveness in magnetic cooling through high-impact publications and key patents. The team has also achieved world-class results and international competitiveness in component manufacturing and non–rare-earth magnetic refrigerant materials.

Principal Researcher Dr. Jong-Woo Kim stated, “Once commercialized, this technology will overcome the limitations of conventional gas-based cooling systems and provide an eco-friendly and stable cooling solution.”

Senior Researcher Dr. Da-Seul Shin added, “Through this creative convergence research project, we aim to further advance magnetocaloric technology and establish a domestic industrial infrastructure for it, while also expanding into the global market.”

More information: Seon Yeong Yang et al, A systematic study of hot deformation mechanisms in La–Fe–Co–Si alloys and the mitigation of defects in hot rolling process, Rare Metals (2025). DOI: 10.1007/s12598-025-03347-2

Leave a Reply