November 21, 2025 by Adrián Takács, field application engineer at ProTek Devices

The global market for industrial Ethernet applications will see strong growth. In one estimate, it’s expected to grow from around $11B in 2023 to nearly $20B by 2030, according to Grand View Research. However, telecommunications application successes are at the mercy of obstacles like circuit protection. As a result, the same research firm found that circuit protection adoption in telecommunications is also being fueled for growth. This is to meet regulatory requirements, and the company needs to protect its subsystem investments from common electrical transients.

For digital signal transmission, especially in high-speed communications, any kind of unwanted change in the signal might cause serious operational performance issues. Choosing the right circuit protection component for an application is a key factor for maintaining five-nines systems operation.

For a common circuit protection configuration, the hardware engineer has to keep in mind that the component needs to fulfill two major points. It must protect the transmission signal against external threats applied to the system from the environment. Some of these threats include the switching of inductive loads, large load changes, grounding and/or bonding issues, utility grid disturbances, and lightning strikes, to name a few. The engineer must also ensure that any additional parasitic properties from the circuit protection component won’t degrade the signal.

Determining electrical transient threats in applications

To determine the extent of external threats, we need to understand the environment where the device will operate. In common telecommunications applications, these can include intra-building or outside of the building, short-haul cables, or long-haul cables connected to devices. It can also mean high temperatures or a poor cooling environment.

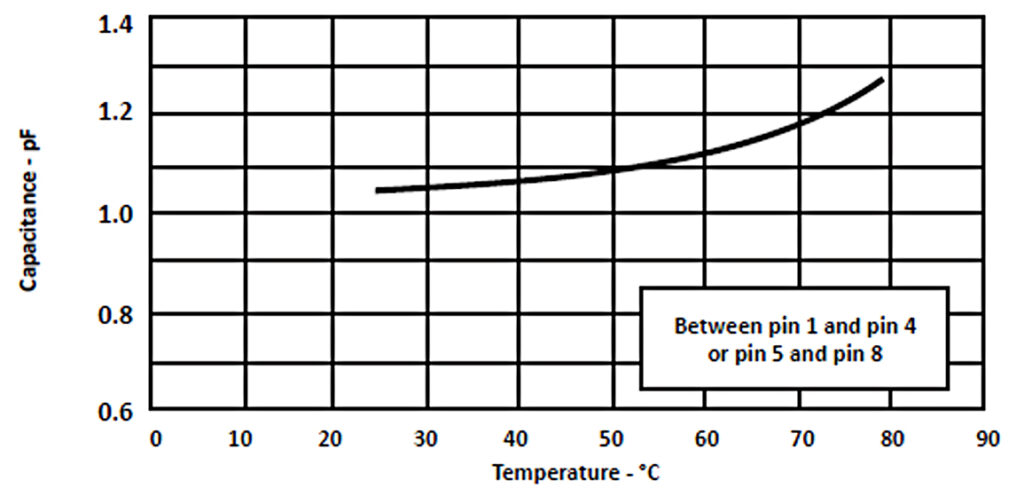

The IEC 61000-4-5 compliance standard can guide designers through surge and lightning levels in different electrical environments. However, another important parameter could be the ambient temperature. It may be elevated above the usual 25 degrees Celsius in the defined environment. Either can impose unique threats.

The role of capacitance in circuit protection

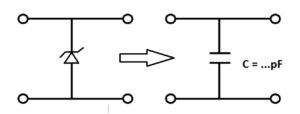

It is also important to mention that with a semiconductor-based surge circuit protection solution, an engineer has to consider parasitic elements. The most important is the capacitance and the reactance, which can easily modify the signal.

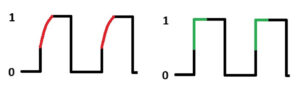

The signal can be considered a high-frequency AC signal, because only the ESR and the reactance of the parallel capacitor are resisting the ground. If the impedance is low, part of the signal is lost due to the current flowing through the capacitor to the ground. This signal distortion when the logic “1” delay occurs is shown in Figure 3.

To calculate the reactance, it is important to know the frequency as well as the actual capacitance value. The equation Xc = 1 / ( 2 × π × f × C ) shows that as the frequency or capacitance is increased, the value of the reactance decreases. This results in the leading edge of the 0-1 transitions starting to smooth out. On the other hand, in the case of a fixed frequency, we can reduce the capacitance. Then, reactance will increase. This results in a more angular rising edge.

The parasitic capacitance is the only thing that could be changed in the formula. It can be reduced by considering the use of a circuit protection component. The ohmic resistance in

the reverse bias is constant and only affected by the nature of the P-N transition. So, that leaves the reduction of capacitance to increase impedance.

What also needs mentioning is the small, unwanted current that flows through the device. When it’s supposed to be “off,” it is called leakage current. The phenomenon is primarily caused by thermal energy. This excites electrons from the valence band into the conduction band. Because of that, mechanism leakage can be even more critical in a raised temperature environment.

Higher surge capability with advanced semiconductor technology

Sustained improvement of Ethernet technology requires continuous development in system robustness. This presents significant challenges for design engineers. Nowadays, the circuit protection provided by transient voltage suppression technology (TVS technology) may not always be sufficient to counteract overvoltage events caused by inductive coupling or high-power transients.

It may be necessary to limit surge energy to a lower level. It’s more commonly necessary so underlying circuits, sensitive to overvoltage, can withstand surges without failure or damage. In this case, a hybrid semiconductor device using a thyristor and TVS combination provides a more ideal solution. The benefit of thyristor technology is its crowbar characteristics when switching on, dumping more energy to ground than a TVS.

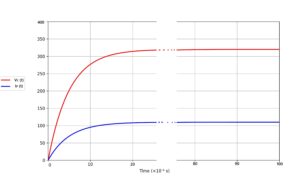

As an example, let’s use a 300 V thyristor device using a single die measuring 100 × 100 square millimeters, which might be exposed to a 10/1000 microseconds surge pulse with a 100 A peak current. This results in an approximate energy dissipation of 0.7 J, with the clamping voltage maintained in the range of 5 V to 8 V.

Compare the results to a 300 V TVS device employing stacked dice with an approximate total area of 320 × 320 square millimeters. The application of the same 10/1000 microseconds surge pulse at a 100 A peak current results in an energy dissipation of approximately 52 J, with the clamping voltage at roughly 345 V.

The thyristor provides high surge capability and small form factors, while the TVS diode delivers small capacitance. The combo makes for a more modern chipset against surge events. It can be concluded that the size of the component is also important. The reduced space nowadays in the printed circuit board requires small-dimension components for circuit protection purposes. This is especially the case if the right part is not included in the schematic at the very beginning of the design phase.

Where traditional avalanche breakdown diodes fit

Avalanche breakdown diodes continue to provide a practical and cost-effective solution for many designs. This is particularly true where high-performance demands are not required. Their effectiveness can diminish in more demanding applications where parameter shifts become limiting factors. These can include voltage accuracy, leakage current, or capacitance.

The development of hybrid semiconductor technology was driven by a need to overcome these limits. It would be suited to applications requiring tighter control over leakage current, which is often difficult to manage with standard junction TVS devices operating at very low breakdown voltages.

Enhanced performance in higher operating temperatures

Variations in environmental conditions further increase critical parameters in determining overall system performance. You must consider surge capability, the prominence of the capacitance and the leakage current, and the importance of the voltage levels, like the clamping and the snapback voltage. These are key to finding an adequate circuit protection solution for elevated temperature environments.

Some components used for overvoltage protection have ultra-low capacitance and also interfere with the signal at advanced temperatures, around 70 to 80 degrees Celsius. Using a new thyristor / TVS hybrid semiconductor array can help overcome such obstacles.

The technology can offer reliable operation in elevated temperatures, thereby ensuring lossless data transfer. Operating in the high-frequency gigabit range, the capacitance should be below 2 pF to fulfill circuit functions without introducing any adverse effects.

As shown in Figure 8, the thyristor / TVS hybrid semiconductor array maintains reliable operation with low capacitance at temperatures exceeding the nominal 25 degrees Celsius reference condition.

As the temperature rises, the device’s ability to dissipate heat decreases. As illustrated in Figure 9, the maximum rated power capability remains constant up to 75 degrees Celsius.

We can analyze the typical leakage current versus junction temperature characteristics, as depicted in Figure 10. This demonstrates that the measured leakage values in the bilateral configuration remain within a low and stable range across the evaluated temperature spectrum.

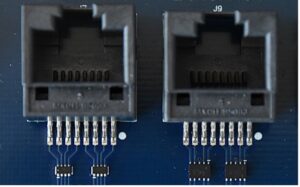

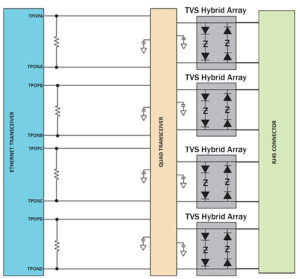

To make designs robust, an effective solution for Ethernet protection is to secure all data lines, as depicted in Figure 9, using the thyristor–TVS hybrid semiconductor array in differential mode. At 50mA, the device’s on-state or snapback voltage is typically 2.35V. This is suitable for the I/O signals that are at ±2.5V.

The continued role of conventional TVS devices

When system requirements are less stringent, conventional TVS devices remain a highly practical option. Their smaller form factor, wider package availability, and cost advantages continue to make them an attractive choice. In applications where surge protection is not mission-critical, employing hybrid semiconductors solely for ESD protection may even introduce unnecessary complexity and overhead.

However, hybrid semiconductor technology represents a leap forward over conventional TVS solutions for environments where parameters such as leakage current and capacitance play a critical role. In some cases, carefully selected avalanche diodes combined with transformer-based architecture can approach a comparable level of protection. Yet, design engineers must balance these technical possibilities against real-world constraints, including limited PCB space and cost sensitivity.

Ultimately, these considerations often determine whether advanced hybrid solutions are justified or whether conventional TVS devices remain the most efficient and pragmatic choice.

Today’s Ethernet communication interfaces can benefit from hybrid circuit protection solutions

Effective circuit protection is critical in today’s and future high-speed communication interfaces, where signal integrity and component reliability must be preserved under harsh electrical and environmental conditions. Selecting the right circuit protection device requires careful balancing of the different electrical parameters, such as capacitance and surge capability, while considering thermal conditions. The newest thyristor / TVS hybrid semiconductor array technologies available today can offer increased circuit protection. This can be critical for high-speed Ethernet running in elevated temperature environments, by helping secure low capacitance and higher capability.

Leave a Reply