September 23, 2025 by Karlstad University

Collected at: https://techxplore.com/news/2025-09-lab-energy-efficient-paper.html

Paper manufacturing is very energy-intensive, but there is great potential for improving energy efficiency. In a comprehensive research project conducted in close collaboration with industry, researchers at Karlstad University have used data modeling and laboratory and pilot-scale experiments to generate new knowledge that can help streamline the processes.

Two papers on the research are published in the journals Drying Technology and Chemical Engineering Research and Design.

“Wood fibers have an incredible ability to retain water and clump together, which poses challenges in the production of paper and paperboard,” says Björn Sjöstrand, docent in chemical engineering at Karlstad University. “To create smooth and even paper products, we must prevent the fibers from clumping together. So, what is the solution? Lots of water. As much as 99.8% water at the start of the process.

“Water helps separate the fibers and creates physical space between them, which makes it possible to create a smooth sheet of paper. However, the next challenge is removing all that water again, which requires an enormous amount of energy. The research project that we just finished focused on improving the efficiency of the dewatering process in the manufacturing of tissue paper, in other words, toilet paper and kitchen roll.”

Energy-efficient dewatering process in tissue paper manufacturing

In the project, researchers studied through air drying of tissue paper, a technique that is particularly energy-intensive but delivers excellent product properties. The findings provide deeper insights into how tissue paper machines and machine clothing can be designed and optimized, especially to save energy during through air drying.

In addition to Sjöstrand as project leader, several researchers and engineers from Karlstad University were involved, along with engineers and operators from the industry and the Knowledge Foundation (KK-stiftelsen). Evaluating the drying process requires extensive studies, which the researchers have undertaken at several levels.

“Our project took a holistic approach, where we worked in sub-projects involving data modeling, laboratory experiments and pilot-scale trials. This provided results that are comparable to those in full industrial-scale processes. The collaboration between us researchers and engineers from both academia and industry has been key to achieving a full understanding of the processes. It’s truly a team effort.

“I believe there is great potential for energy savings if we continue to focus on process engineering research while working together to gain a better understanding of pulp and paper manufacturing and its processes,” says Sjöstrand.

“The strength of this project lies in the scope of expertise and access to both materials and processes. With a focus on the processes and an understanding of all four scales, from modeling to full-scale production, we can truly make a difference. Our findings are relevant to the entire industry, from global machine manufacturers to start-ups developing new forest-based materials. The aim is also to create a tool for the industry to help optimize their processes. Better processes save resources, reduce the environmental impact and strengthen competitiveness. This is the future for sustainable manufacturing.”

The research team has just launched a new project on the same theme. “In this new project, we are taking a broader approach, covering all manufacturing processes that use forest-based raw materials, still with a focus on models for energy efficiency. Interested companies are welcome to contact us if they wish to participate, with no requirements for funding or prior knowledge,” says Sjöstrand.

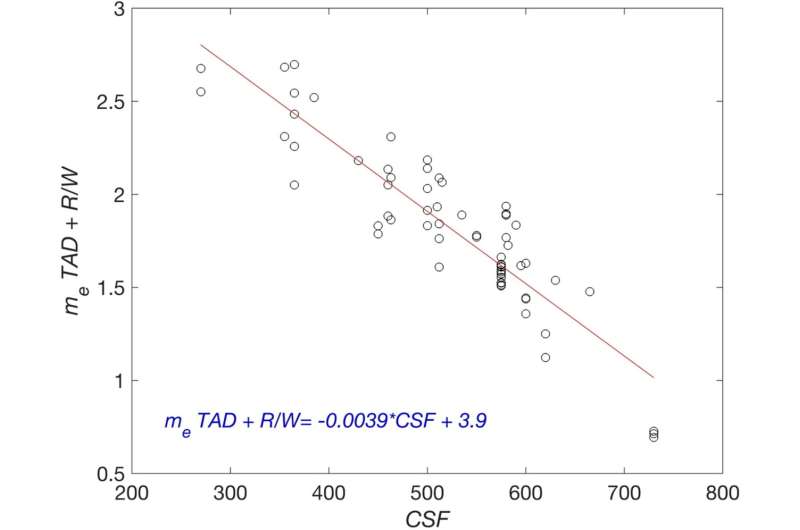

More information: Björn Sjöstrand, Easy-to-use numerical models of water removal in vacuum dewatering and molding during through air drying of tissue paper, Drying Technology (2025). DOI: 10.1080/07373937.2024.2449177

Kamal Rezk et al, Investigation of sheet molding during through air drying of tissue paper: A comparative numerical and experimental study of the solid content, Chemical Engineering Research and Design (2025). DOI: 10.1016/j.cherd.2025.08.037

Leave a Reply