February 2, 2026 by Kaitlyn Landram, Carnegie Mellon University Mechanical Engineering

Collected at: https://techxplore.com/news/2026-02-ai-3d-defects-real.html

Additive manufacturing has revolutionized manufacturing by enabling customized, cost-effective products with minimal waste. However, with the majority of 3D printers operating on open-loop systems, they are notoriously prone to failure. Minor changes, like adjustments to nozzle size or print speed, can lead to print errors that mechanically weaken the part under production.

Traditionally, manufacturers fix these issues on a case-by-case basis, ultimately “babysitting” the printer to manually adjust parameters and test samples in an effort to figure out what went wrong.

New LLM tackles 3D print failures

Amir Barati Farimani, Associate Professor of Mechanical Engineering at Carnegie Mellon University, is automating 3D printing with a new large language model that fixes printer errors in real time without the need for any pre-training. The model is printer-agnostic and can be used by a wide range of printers for varying materials.

“Just three years ago, this type of technology wouldn’t have been possible,” said Yayati Jadhav, Ph.D. candidate and the first author of this research published in Additive Manufacturing.

“Today, LLMs have access to nearly the entire body of human knowledge, but the challenge was extracting only the most relevant pieces. We needed a model to identify 3D printing errors, explain them in plain language, and autonomously correct the problem in real time.”

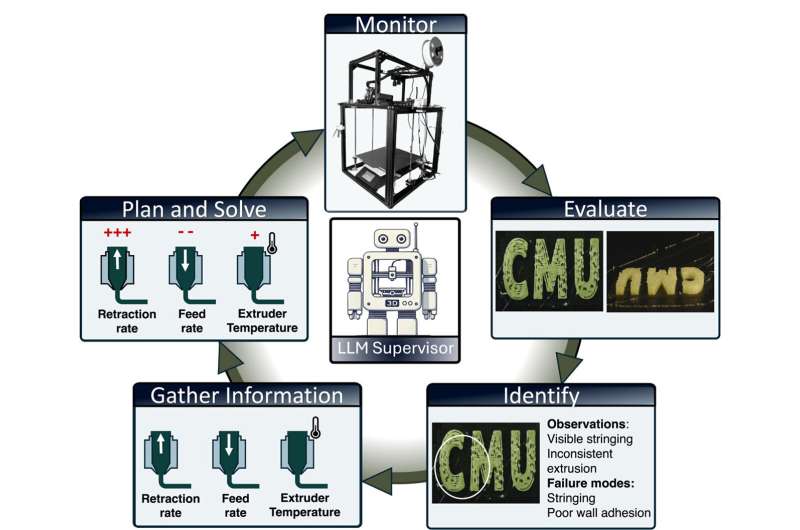

The system works because a multi-agent framework, made up of four specialized LLM agents, enables a continuous cycle of improvement for the open loop system. The modular agents are coordinated by a supervising agent that manages the entire quality-control process.

The motivation for the framework draws inspiration from the structure of a symphony orchestra: the maestro selectively brings in specific sections of expert musicians depending on the passage being performed. Each section works with a high degree of independence, contributing its specialized capability while remaining aligned with the overall composition.

How the orchestral framework works

Operating in a continuous loop, cameras capture top and front images of each completed layer. A vision-language model analyzes the images to detect defects and assess print quality, while planner agents evaluate the printer’s state (temperature, material flow rate, etc.) and formulate a corrective action plan. Executor agents then translate the plan into machine-readable commands and deliver real-time, actionable feedback to the printer.

In their framework, the supervisor plays a similar role. It cues each module when appropriate, invoking the experts best suited for the current stage of the problem. Each module then performs its specialized task and reports back to the supervisor once its part is complete. This allows the system to operate in a coordinated yet modular fashion, mirroring the orchestral model of distributed expertise under centralized guidance.

Performance gains and real-world appeal

Parts manufactured using the LLM exhibited significantly enhanced structural integrity and a 5.06x increase in peak load capacity. When tested head-to-head against 14 additive manufacturing experts, the LLM consistently identified major failure modes with high accuracy.

Jadhav noted that the system’s modular design makes it especially appealing for companies concerned with data security.

“Manufacturers can protect their intellectual property while still allowing external partners access only to part-specific modules needed to print components,” he explained.

Toward adaptive, autonomous manufacturing

Additionally, the framework generates detailed commentary, allowing the engineers behind the parts to understand exactly what went wrong in the print.

“The future is adaptive,” said Barati Farimani. “The integration of LLMs into the 3D printing process represents a significant advancement. As these models evolve, their ability to reason over richer, multimodal data will unlock even more capabilities. For now, this work provides a foundation for truly intelligent and autonomous manufacturing systems, capable of achieving unprecedented levels of precision and reliability.”

More information: Yayati Jadhav et al, LLM-3D print: Large Language Models to monitor and control 3D printing, Additive Manufacturing (2025). DOI: 10.1016/j.addma.2025.105027

Leave a Reply