By Tokyo Metropolitan University December 4, 2025

Collected at: https://scitechdaily.com/scientists-crack-the-foam-drainage-puzzle-after-decades-of-mystery/

New observations show that foam drainage is controlled by bubble rearrangement, not traditional surface-tension models.

Researchers at Tokyo Metropolitan University have uncovered the solution to a long-standing question about how liquid escapes from foams. Traditional physics models predict that foams must be far taller before any liquid can drain from the bottom, but real-world behavior contradicts those estimates.

By closely examining how foams behave, the team discovered that drainage begins when the pressure is high enough to force bubbles to shift position rather than simply push liquid through a fixed network. Their findings show that the movement of bubbles plays a key role in understanding how soft materials function.

When foam is sprayed onto a surface, droplets often appear below it. This happens because foams consist of tightly packed bubbles separated by thin liquid films, creating a complex network of channels. Liquid can flow through these passages, allowing it either to leave the foam or to draw in additional liquid when new fluid touches the surface. The point at which this occurs, known as the “absorptive limit”, has traditionally been linked to “osmotic pressure”, which describes the energy change that occurs when bubbles are compressed and their liquid-gas contact areas shift.

The Problem With Existing Models

Or so it was believed. For many years, scientists have struggled with calculations that predict how tall a foam must be for this limit to take effect. Estimates based on osmotic pressure, which depends on bubble size and surface tension, suggest that a foam should reach roughly a meter in height before drainage begins. Yet in practice, even foams only a few tens of centimeters tall can lose liquid with ease.

Foams play a major role in everyday products, from household cleaners to pharmaceutical formulations. To develop materials tailored for specific purposes, such as foams that hold liquid more effectively, it is essential to understand the underlying physical processes that govern how they behave.

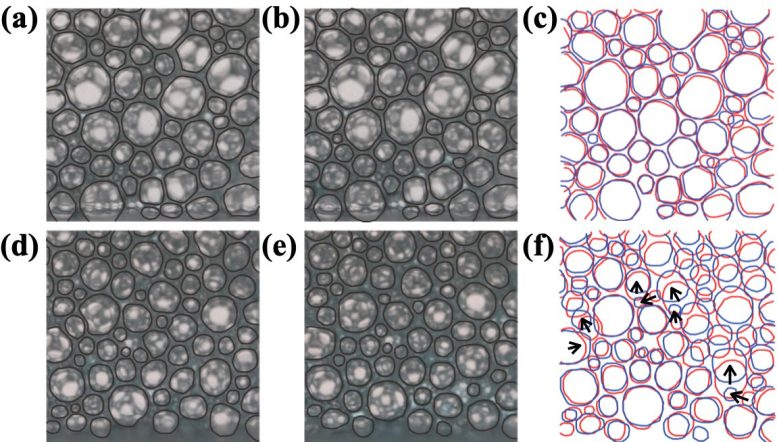

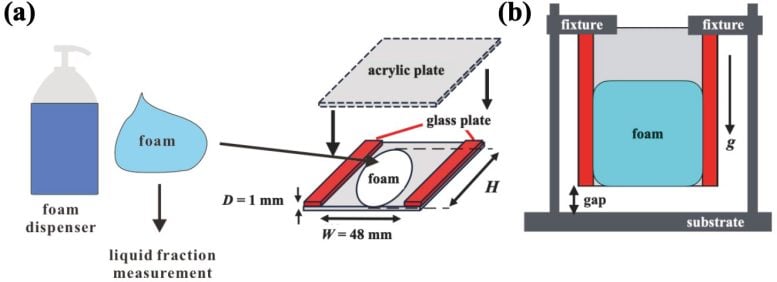

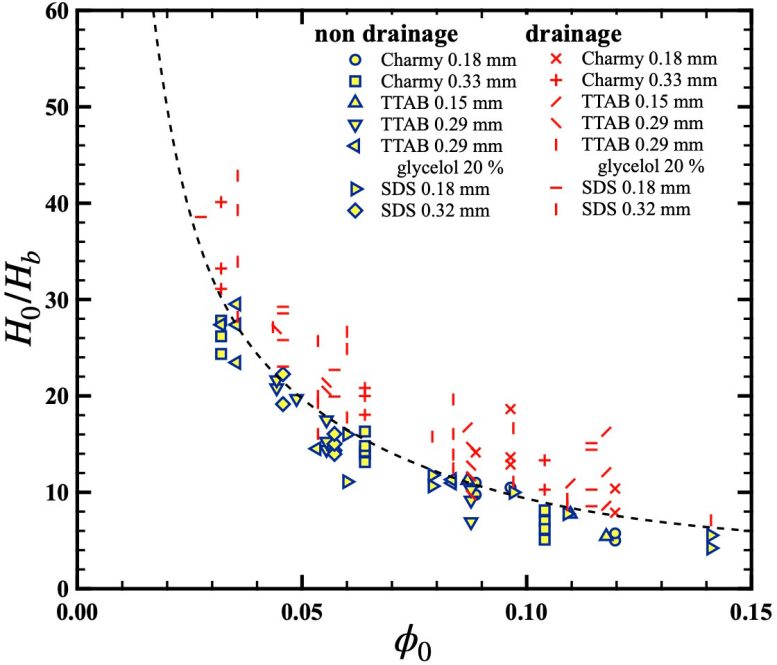

A team led by Professor Rei Kurita of Tokyo Metropolitan University has been looking at drainage in simple foams. The team used various surfactants to create a library of different foams with different properties, sandwich them between transparent plates, and stand them upright to reveal what is going on inside while they drain, if at all.

Firstly, they discovered a universal behavior where the height at which drainage starts is inversely proportional to the liquid fraction of the foam, independent of surfactant type or bubble size. Their analysis of the limit yields an “effective osmotic pressure” at which the absorptive limit is met significantly lower than what is expected from bubble sizes and surface tension.

Discovering the Real Limiting Factor

Going back to the drawing board, the team looked directly inside the foam with a video camera. For foams that have just made it to the drainage point, they discovered that liquid wasn’t simply pushing through the maze of connections but causing the bubbles themselves to rearrange. They found that the limit where drainage occurs is determined not by surface tension but “yield stress,” the amount of pressure required to rearrange bubbles. Importantly, this model gives heights for draining foams that match up with reality.

This result upends the fundamental picture of how we look at foam drainage, from a static picture of liquid moving through gaps, to a dynamic one where the gaps themselves can move. The team hopes their findings inspire new insights into the behavior of soft materials, as well as approaches to designing better foam products.

Reference: “Absorptive limits of foams governed by kinematic coupling between solution and bubbles” by Aoi Kaneda and Rei Kurita, 5 May 2025, Journal of Colloid and Interface Science.

DOI: 10.1016/j.jcis.2025.137746

This work was supported by JSPS KAKENHI Grant Number 20H01874.

Leave a Reply