December 2, 2025 by Pusan National University

Collected at: https://techxplore.com/news/2025-12-ai-optimized-components-outperform-human.html

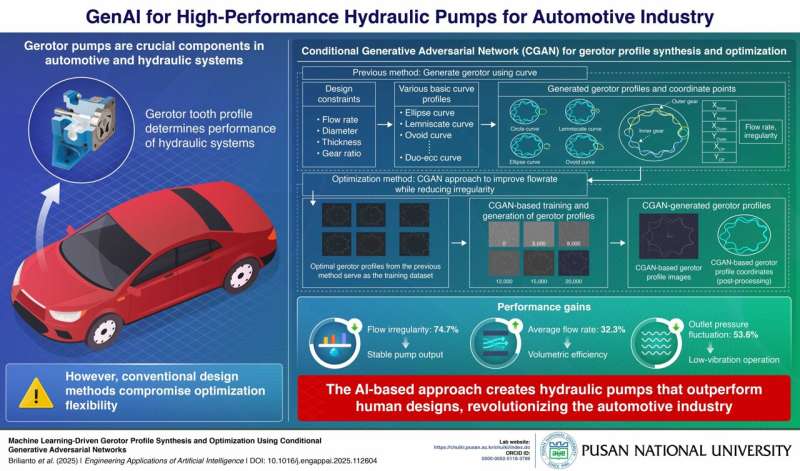

Gerotor pumps for oil circulation and lubrication are crucial components in automotive and hydraulic systems. They possess a compact design, excellent flow rate per rotation, and high suction capability. The gerotor tooth profile plays a significant role in determining the overall performance of hydraulic systems for engine lubrication and automatic transmission.

Unfortunately, conventional design methods leverage predefined mathematical curves and iterative adjustments, which compromises their optimization flexibility.

Researchers develop AI-driven design method

A team of researchers from the School of Mechanical Engineering at Pusan National University, led by Professor Chul Kim, has proposed a new design methodology.

Their findings are published in Engineering Applications of Artificial Intelligence.

The key point of this study is the use of AI, specifically, a conditional generative adversarial network, as a design tool. Instead of relying on the traditional approach of using predefined mathematical curves, the researchers trained an AI to automatically generate new gerotor profiles.

The AI learned from a dataset linking specific, high-performance profile geometries to their actual performance data. This innovation allowed it to understand why certain shapes perform better than others, and then generate new, highly-optimized geometries that substantially outperform traditional designs.

Performance improvements and real-world impact

The team demonstrated that their novel AI-generated design exhibits substantial performance gains in simulation validation via computational fluid dynamics.

Compared to a traditional ovoid profile, the proposed design achieved a 74.7% reduction in flow irregularity. This means the pump’s output is significantly more stable and consistent. It also shows a 32.3% increase in average flow rate, which indicates better volumetric efficiency, as well as a 53.6% reduction in outlet pressure fluctuation, which directly contributes to quieter operation and reduced vibration.

The most direct real-life applications of the present work are in the automotive industry. The reduction in pressure fluctuation and flow irregularity is highly beneficial here. It can lead to transmission systems that operate more quietly and could potentially improve component reliability by reducing vibration and unstable hydraulic stress.

Furthermore, the 32.3% increase in average flow rate allows for more efficient oil circulation throughout the engine. This contributes to better lubrication and cooling of engine components, which is critical for engine durability.

Future potential and broader applications

Prof. Kim said, “The same principles demonstrated in our study are applicable to various hydraulic pumps used in industrial machinery, where efficiency, low noise, and reliability are important factors, making our technology highly lucrative for real-life adoption.”

In the next five to 10 years, methods like this could become a standard tool for engineers. It represents a move toward “inverse design,” where an engineer can specify the desired performance targets, such as “minimize pressure fluctuation,” and the AI assists in generating an optimal geometry to meet those targets.

Moreover, this approach can speed up the research and development cycle for complex mechanical components. It allows for the exploration of a much wider design space than is possible through traditional manual iteration.

“Crucially, for the public, the adoption of more optimal components can mean the machines we use daily become quieter and more reliable. In the automotive sector, this translates to vehicles with more efficient and durable hydraulic systems like transmissions and oil pumps,” concludes Prof. Kim.

More information: Rivaldo Mersis Brilianto et al, Machine learning-driven gerotor profile synthesis and optimization using Conditional Generative Adversarial Networks, Engineering Applications of Artificial Intelligence (2025). DOI: 10.1016/j.engappai.2025.112604

Leave a Reply