Tanya Weaver Tue 21 Oct 2025

Collected at: https://eandt.theiet.org/2025/10/21/3d-printed-antennas-pave-way-wearable-and-flexible-wireless-tech

3D‑printed flexible antenna arrays could power wearable wireless devices and improve communications across various applications, according to a new study.

Researchers at Washington State University (WSU) have developed the antennae and a chip-sized processor using 3D printing techniques with ink made from copper nanoparticles.

This ink, developed in collaboration with researchers from the University of Maryland and Boeing, allows the antennae to remain stable when bent or exposed to high humidity, temperature variations or salt.

The processor chip corrects errant signals from the antennae in real time, enhancing the performance and electronic communications of the flexible wireless system.

Sreeni Poolakkal, co-first author and PhD student at WSU, said: “This proof-of-concept prototype paves the way for future smart textiles, drone or aircraft communications, edge sensing, and other rapidly evolving fields that require robust, flexible and high-performance wireless systems.”

While the aviation, automotive and space industries would benefit from 3D-printed antenna arrays over traditional ones because of their flexibility, compact size and light weight, previous iterations have been too expensive to develop and have lacked the performance requirements needed.

For instance, when these antennae move, bend or vibrate, the antennae change shape causing errors in their signals.

Subhanshu Gupta, associate professor at WSU and study co-author, said: “The ink is a very important part in additive, or 3D printing. The nanoparticle-based ink developed by our collaborators is actually very powerful in improving the performance for high-end communication circuits like what we’re doing.”

As precision wireless communication needs significant fidelity, the researchers developed a processor chip capable of correcting material deformities and vibrations in the 3D-printed antennae in real-time.

Gupta said: “The ability to do that in real time makes it very attractive. We were able to achieve robust, real-time beam stabilisation for the arrays, something that was not possible before.”

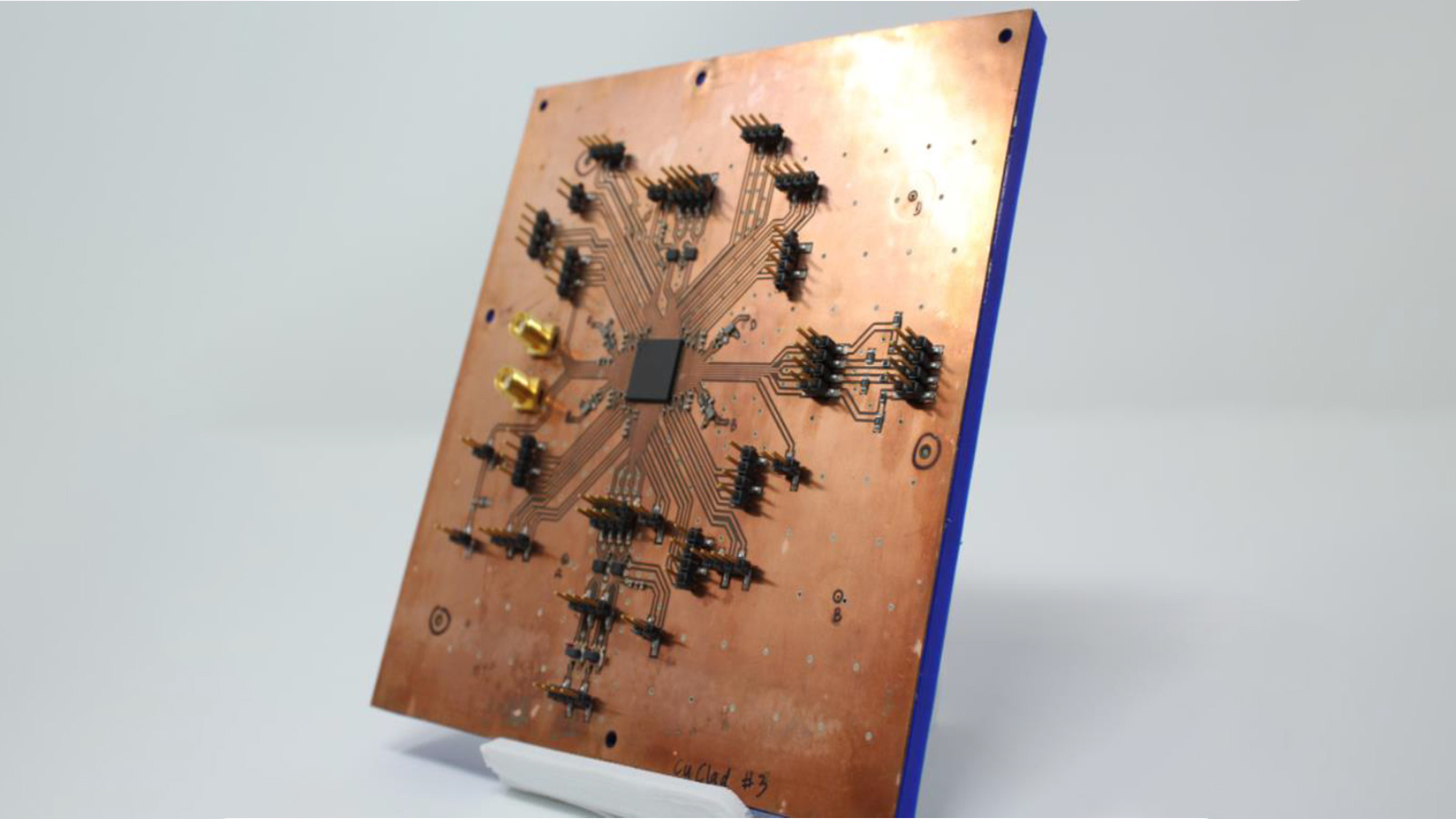

To test their system, the researchers built a lightweight, flexible array of four antennae that were able to send and receive signals successfully when the antennae were moving and bending.

Washington State University

The antennae use low power and can easily be scaled. Gupta says that, because they’re built as tiles, this design enables larger arrays to be built, with individual processor chips on each of the tiles operating independently.

The researchers were able to put together four of the antenna arrays to make 16 total antennae.

Their study – ‘Dynamic beam-stabilized, additive-printed flexible antenna arrays with on-chip rapid insight generation’ – has been published in Nature Communications.

Leave a Reply